BESS Power Station: Electronically Controlled Intelligent Multi- Sprayed Compressed Air Foam Extinguishing System

Description

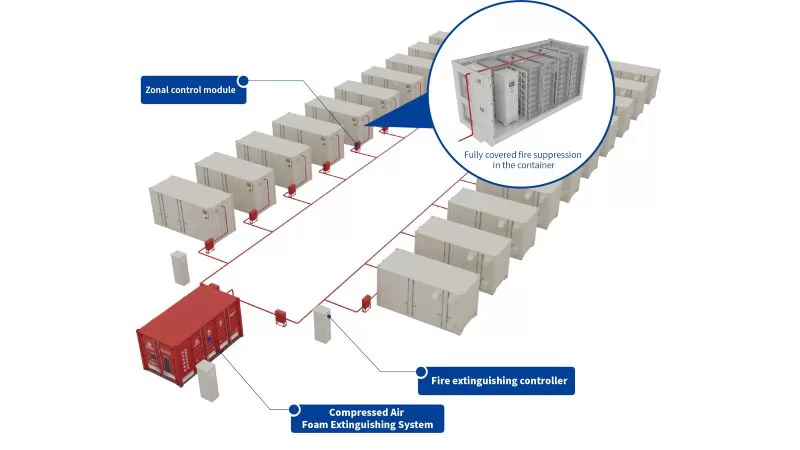

In order to meet the growing fire protection needs of energy storage power station, this system has been innovatively developed, which can simultaneously perform "container-level" total- flooding, immersed, and multi-directional fire protection for multiple BESS units.This system can realize all-weather protection for multiple BESS units by integrating a number of leading technologies such as PHP pressure balanced foam proportioning system, intelligent centralized management, precise container-level spraying, multi-sprayed thermal runaway expansion & suppression, etc. When a fire occurs, it can perform accurate extinguishing; Equipped with a large-capacity extinguishant, it can carry out multiple long-term suppression of fires in the BESS units; Comprehensively using the emerging information technologies such as IoT, cloud computing, and big data, it can realize the intelligent visual management, present real-time fire protection dynamics in the most intuitive way, which greatly improves the fire protection risk management and comprehensively guarantees the safe and reliable operation of the equipment in electrochemical energy storage power station.

System Feature

1.Centralized intelligent management

The solution adopts the centralized fire suppression system, with the compressed air foam extinguishing device as the center. The pipeline length is up to 100m, and can be connected to up to 200 containers. This system can conduct automatic and accurate all-weather fire extinguishing and conduct the operation status monitoring of the fire extinguishing system in the BESS, and upload the information in real time to the fire alarm controller, which can be quickly viewed and managed on the display device at the fire alarm controller.

2.Precise multiple suppression

This system adopts built-in 600L extinguishant storage tank. When the energy storage container is used as the protected unit, the extinguishant can be continuously sprayed for at least 120min; if the intermittent spraying for continuous suppression and cooling are used, more than 100 spraying can be carried out.

3.Industrial control environment adaptation

The system is equipped with industrial-grade multi-functional air conditioners, dehumidifiers, exhaust fans and electric heating devices, which can realize the intelligent control of humidity and temperature in the cabin, and provide a strong guarantee for the stable equipment operation under various environmental conditions.

4.Long-distance and high-efficiency suppression

The system is equipped with strong power, and the longest distribution distance can reach up to 100m, and it still maintains strong extinguishing power at the farthest end, so that the system can provide flexible layout solutions according to the working conditions and environments of the project site.

5.Backup support

In order to further ensure the effectiveness, the system adopts the design of one use and one standby for the key power module, with standby power available, which can effectively prevent the failure of the fire extinguishing system caused by the sudden failure of its power source when the alarm occurs, and can effectively guarantee the operation stability of the fire extinguishing system.

6.Intrinsically safe prevention and control

In order to comprehensively prevent and control the fire risks in the energy storage power station, the equipment cabin itself has a full set of fire alarm system and automatic fire extinguishing system, which can monitor the status of the equipment itself in real time. When there is an emergency, it can be activated in time and quickly send out an alarm signal for automatic fire extinguishing, which can effectively ensure the safe operation of the equipment.

Fire Suppression System

| Item | Specification & Parameter |

|---|---|

| Operating voltage | AC380V,50HZ |

| Maximum power | 65W |

| Ambient temperature | -40C~+55C |

| Protection class | IP55C4 |

| Rated working pressure | 0.8 MPa |

| Rated flow rate | 400L/min |

| Continuous working time | ≥120min |

| Extinguishant | AFFF:1% |

| Gas-liquid ratio | 6:1-10:1 |

| Expansion | 10.74 |

| Maximum protected BESS unit per zone | 30 |

| Maximum zone number | 12 |

| Spraying number | Sprayed at intervals of 15 minutes for 24 hours |

| Communication mode | 485/61850/Passive dry contact |

| Dimension | 5500mm*3000mm*2900mm |

| Weight | No load:6.5 tons; Full load:16 tons |