How Does a Foam Fire Suppression System Work? — JUAND

A foam fire suppression system is a specialized fire protection solution designed to control and extinguish flammable liquid fires by forming a protective foam blanket over the fuel surface. Backed by over 16 years of industrial fire research and 11 years of lithium-ion battery fire studies, JUAND develops advanced foam suppression technologies that help safeguard critical facilities, industrial operations, and high-risk environments.

What Is Foam Fire Suppression?

Foam fire suppression is a fire protection method that uses a mixture of water, foam concentrate, and air to create a stable layer of bubbles capable of controlling and extinguishing flammable liquid fires. Unlike traditional water-based systems that struggle with fuel-based fires, foam is designed to float on the surface of combustible liquids, forming a thick and cohesive barrier that prevents ignition and suppresses vapors.

In industrial settings where fuels, chemicals, oils, or solvents are present, foam systems offer fast and reliable protection. As a leading fire suppression manufacturer with over 400 team members, 50+ standards and codes, and more than 200 patented technologies, JUAND engineers foam solutions that meet the safety demands of complex and high-risk environments.

How Foam Extinguishes Fire: The Four Core Mechanisms

1. Fuel Surface Coverage

Foam forms a continuous blanket that spreads across the surface of burning fuel. This layer separates the fuel from surrounding oxygen, interrupting the fire triangle and quickly reducing flame intensity. By blocking oxygen, the foam blanket also prevents the fire from rekindling even after the flames are initially suppressed.

2. Cooling Effect

Although foam appears light and airy, it contains a significant amount of water within its bubble structure. When the foam is applied, this water slowly drains onto the fuel surface, providing an effective cooling action. Lowering the temperature of the fuel reduces the chance of re-ignition and supports sustained fire control.

3. Vapor Suppression

Flammable liquid fires often continue to burn because they release hazardous vapors. Foam systems inhibit this process by sealing the fuel surface and preventing vapor release. Without the continuous supply of vapors, the fire loses its primary source of combustion, resulting in faster extinguishment.

4. Preventing Re-Ignition

A crucial benefit of foam is its ability to stay in place after the flames are extinguished. The foam blanket remains stable over time, protecting the fuel surface from heat, sparks, and oxygen exposure. This long-lasting barrier ensures that even if surrounding conditions change, the fire is far less likely to reignite.

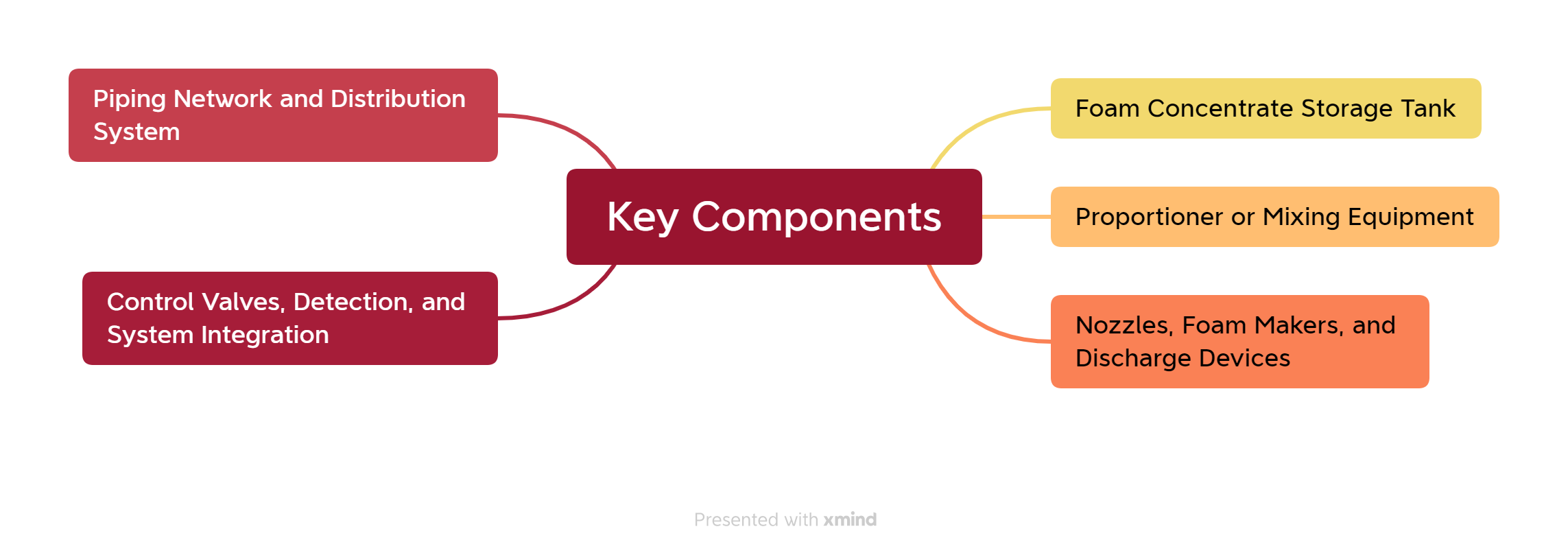

Key Components of a Foam Suppression System

A foam fire suppression system consists of several integrated components that work together to produce, mix, and distribute foam effectively. Each part plays a critical role in ensuring reliable system performance during emergencies, especially in high-risk industrial environments.

Foam Concentrate Storage Tank

The foam concentrate tank stores the chemical agent that will be mixed with water to create foam. Depending on system design, the tank may be atmospheric, pressure-rated, or part of a bladder tank assembly. Proper storage ensures stable foam quality and consistent performance during discharge.

Proportioner or Mixing Equipment

The proportioner precisely blends foam concentrate with water at the correct ratio. Common proportioning devices include balanced-pressure systems, in-line eductors, and bladder tank proportioners. Accurate proportioning is essential for producing foam with the required expansion and extinguishing characteristics.

Piping Network and Distribution System

Pipes, valves, and fittings deliver the foam solution throughout the facility. These components must be corrosion-resistant and compatible with foam concentrates. A well-engineered piping network ensures uniform foam coverage across the protected hazard area.

Nozzles, Foam Makers, and Discharge Devices

Foam is discharged through specialized devices such as aspirating nozzles, foam chambers, monitors, or high-expansion foam generators. These components introduce air into the mixture to create bubbles and distribute foam effectively over the fuel surface or into large enclosed spaces.

Control Valves, Detection, and System Integration

Foam systems integrate with fire detection sensors, actuation valves, alarm panels, and control logic to ensure fast and automatic response. When a fire is detected, the system activates relevant discharge devices, allowing foam to be applied within seconds to contain the hazard.

Foam Types & Expansion Ratios: How to Choose

Foam fire suppression systems are categorized by the type of foam concentrate used and the expansion ratio achieved during discharge. Understanding these differences helps facility managers select the right foam solution for their specific fire risks and operating environments.

Low-Expansion Foam (2:1–20:1)

Low-expansion foam produces a dense, stable blanket ideal for controlling flammable liquid fires such as fuel spills, tank farms, and industrial process areas. Its strong surface coverage and slow drainage rate make it particularly effective for extinguishing Class B fires.

Medium-Expansion Foam (20:1–200:1)

Medium-expansion foam offers fast coverage with lower water usage, making it suitable for semi-enclosed spaces, loading docks, chemical storage areas, and waste-handling sites. It spreads quickly and is effective when rapid area filling is required.

High-Expansion Foam (>200:1)

High-expansion foam generates large volumes of lightweight foam, allowing it to fill entire rooms or enclosures. It is commonly used in aircraft hangars, warehouses, tunnels, and areas where complete volume flooding is the most effective suppression strategy.

Fluorinated vs. Fluorine-Free Foam Concentrates

| Foam Type | Characteristics | Advantages | Considerations |

|---|---|---|---|

| Fluorinated Foam (AFFF, FFFP) | Contains fluorosurfactants for fuel-shedding | Strong performance on hydrocarbon fires, fast flame knockdown | Environmental restrictions in some regions |

| Fluorine-Free Foam (FFF) | Free of fluorosurfactants, environmentally safer | Preferred in regions with strict environmental regulations | May have slightly lower fuel-shedding capability compared to fluorinated foams |

Factors to consider when selecting foam type:

- Type of fuel present (hydrocarbon vs. polar solvents)

- Required coverage speed and fire risk

- Indoor vs. outdoor hazard location

- Environmental regulations and compliance requirements

- Complexity or high-risk application (may require expert assessment)

JUAND’s engineering team can conduct hazard assessments to recommend the most effective foam solution tailored to your facility and compliance needs.

Typical System Types & Configurations

Foam fire suppression systems can be engineered in several configurations depending on the nature of the hazard, the size of the facility, and operational requirements. Each system type offers unique advantages for different industrial scenarios.

Fixed Water-Foam Systems

Fixed foam systems are permanently installed and designed to protect high-risk areas such as fuel storage depots, chemical processing zones, and large industrial plants. These systems automatically discharge foam when a fire is detected, ensuring rapid suppression with minimal operator intervention.

Mobile or Vehicle-Mounted Foam Systems

Mobile foam units are mounted on fire trucks, trailers, or portable skids. They provide flexible protection for outdoor facilities, remote areas, or operations that require high-response mobility. These systems are common in fuel transport fleets, logistics hubs, and emergency response teams.

High-Expansion Foam Generators

High-expansion generators are used for environments that require total flooding protection, such as aircraft hangars, storage warehouses, turbine halls, and tunnels. By producing large volumes of foam quickly, these systems can fill expansive spaces to suppress fires in areas where direct application is difficult.

Local Application Systems

Local application foam systems target specific, high-risk equipment—such as fuel pumps, transformers, or process machinery. They deliver foam directly onto the hazard area, offering efficient suppression while minimizing unnecessary foam discharge in surrounding zones.

Total Flooding Systems

Total flooding systems are designed to protect entire rooms or enclosed areas by filling the space with foam. This approach is ideal for large-volume hazards where a fire could spread rapidly or where the fuel is distributed across multiple surfaces.

Each system configuration must be selected based on fuel type, facility layout, airflow conditions, environmental concerns, and operational continuity requirements. JUAND’s engineering team can design tailored foam suppression solutions backed by extensive industrial research and testing data.

Where Are Foam Fire Suppression Systems Used?

Foam fire suppression systems are essential in industries where flammable liquids, hazardous chemicals, or high-risk storage conditions are present. These systems provide rapid fire control, prevent re-ignition, and offer reliable protection for mission-critical operations. With 16 years of industrial fire research and over 200 patented technologies, JUAND delivers high-performance foam systems trusted across global industries.

- Petrochemical plants and refineries – Ideal for protecting fuel processing areas, storage tanks, and transfer zones.

- Aircraft hangars – Foam rapidly suppresses jet-A fuel fires and protects large indoor aviation facilities.

- Fuel storage depots – Prevents fire spread across bulk fuel tanks and loading stations.

- Warehouses handling flammable liquids – Controls hazards in chemical warehouses and industrial distribution centers.

- Marine and offshore platforms – Provides fast suppression for engine rooms, deck fuel areas, and offshore rigs.

- Battery energy storage systems (BESS) – JUAND’s foam solutions align with 11 years of lithium-ion battery fire research to manage thermal runaway-related hazards.

Advantages of Foam Fire Suppression Systems

Foam fire suppression systems offer powerful fire-control capabilities, especially for Class B flammable liquid fires. With extensive industrial fire research experience and more than 50 technical standards contributed by JUAND, these systems provide dependable protection for both conventional and high-risk environments.

- Rapid fire knockdown: Foam spreads quickly across the fuel surface, suppressing flames within seconds.

- Prevents re-ignition: The foam blanket separates oxygen from the fuel and cools surrounding surfaces.

- Highly effective for flammable liquids: Ideal for petroleum, aviation fuel, chemicals, solvents, and other hazardous liquids.

- Scalable for various facility sizes: Systems can be engineered for small rooms, large warehouses, or outdoor tank farms.

- Compatible with multiple discharge methods: Works with sprinklers, monitors, deluge systems, rim-seal equipment, and proportioning devices.

- Reliable performance backed by research: JUAND’s 200+ patented technologies and 18+ major research projects ensure proven, science-based fire suppression results.

Components of a Foam Fire Suppression System

A foam fire suppression system is built from several key components that work together to detect a fire, proportion the correct foam mixture, and deliver foam to the hazard area. JUAND integrates advanced engineering, proprietary technologies, and strict quality standards to ensure each component performs reliably in demanding industrial environments.

- Foam Concentrate Storage Tank: Holds the foam concentrate used to mix with water. These tanks are engineered for stability, corrosion resistance, and long-term service.

- Proportioning System: Accurately mixes foam concentrate with water at the correct ratio. Includes balanced pressure proportioners, bladder tanks, and in-line inductors designed for precise and stable foam solution delivery.

- Piping Network: Distributes mixed foam solution throughout the facility. Industrial-grade pipes ensure consistent flow even under high-pressure conditions.

- Foam Discharge Devices: Such as sprinklers, nozzles, monitors, foam chambers, and pourers. These devices control how foam is applied—either locally on spills or across large tank areas.

- Fire Detection and Control System: Automatically activates foam discharge when heat, smoke, or flame is detected. JUAND systems integrate with modern alarm panels to provide rapid response.

- Pumps and Water Supply: Ensure reliable water flow for mixing and foam generation. May include fire pumps, jockey pumps, or connection to municipal supply.

- Backup Power and Valves: Provide uninterrupted operation and allow safe isolation, maintenance, or manual activation.

How Does a Foam Fire Suppression System Work?

Foam fire suppression systems operate through a coordinated sequence that detects a fire, activates proportioning equipment, and discharges foam to suppress flames and prevent re-ignition. With over 18 major research projects and a deep understanding of industrial fire behavior, JUAND engineers optimized system response to ensure maximum reliability in high-risk environments.

1. Fire Detection

The system begins operating when heat, smoke, or flame detectors sense abnormal conditions. Detection devices send a signal to the fire control panel, which triggers the foam suppression system.

2. System Activation

Once activated, valves open automatically, pumps start running, and the system prepares to release foam. Activation can be fully automatic or manually triggered using emergency release stations.

3. Proportioning of Foam and Water

Water flows through the proportioning system, where it is accurately mixed with foam concentrate at a specific ratio. JUAND designs its proportioners to maintain consistent mixing even under fluctuating pressure or flow conditions.

4. Foam Generation

The foam solution is delivered to discharge devices—such as nozzles, sprinklers, or monitors—which introduce air into the mixture, expanding it into finished foam.

5. Foam Discharge and Application

Foam spreads across the surface of flammable liquids, forming a stable and insulating blanket that cools the area, blocks oxygen, and prevents fuel vapors from escaping.

6. Fire Suppression and Re-Ignition Prevention

The foam layer suppresses flames almost immediately and maintains coverage long enough to prevent re-ignition. This ensures safer conditions for emergency personnel and reduces damage to facilities.

Why Choose JUAND for Foam Fire Suppression Systems?

Selecting the right foam fire suppression system is critical for industrial safety. With deep expertise in flammable liquid fire behavior and advanced engineering capabilities, JUAND delivers high-performance foam systems trusted across global industries. Our solutions combine rigorous research, patented technologies, and strict quality standards to ensure maximum fire protection.

- 16+ Years of Industrial Fire Research: Extensive experience in understanding and mitigating fire risks in petrochemical, energy, manufacturing, and logistics facilities.

- 11 Years of Lithium-Ion Battery Fire Research: Specialized expertise enabling JUAND to engineer foam solutions suitable for emerging risks such as BESS and EV battery-related fires.

- 400+ Member Professional Team: A multidisciplinary team supporting product design, testing, engineering, and technical service.

- 18+ Major Research Projects: In-depth participation in national and industry-level fire protection research initiatives.

- 50+ Standards & Codes Contributions: Active involvement in developing fire protection standards, ensuring JUAND solutions meet the highest safety requirements.

- 40+ Science & Technology Awards: Recognition for innovation, performance, and contributions to industrial fire safety.

- 200+ Patented Technologies: Proprietary designs that enhance the efficiency, reliability, and intelligence of JUAND foam suppression systems.

Conclusion

Foam fire suppression systems are an essential solution for protecting facilities, industrial operations, and high-risk environments from flammable liquid fires. By combining fuel isolation, cooling, vapor suppression, and re-ignition prevention, these systems offer reliable and rapid fire control. With JUAND’s 16 years of industrial fire research, specialized lithium-ion battery fire expertise, and over 200 patented technologies, businesses can trust in highly engineered foam solutions tailored to meet complex fire protection needs.

For facility managers and safety engineers seeking effective fire suppression strategies, JUAND provides customized foam systems, expert guidance, and ongoing support to ensure optimal performance. Contact JUAND today to learn how our foam fire suppression solutions can safeguard your operations and protect lives.